Traditional silicon-based solar panels often struggle with fluctuating weather conditions in some parts of Japan. To address this, a research team from the University of Tokyo has developed solar panels made from titanium. These new panels are designed for durability and extended lifespan, capable of withstanding harsh climatic conditions. This makes them potentially more efficient in the long term for generating electricity from the same amount of light, compared to conventional silicon cells.

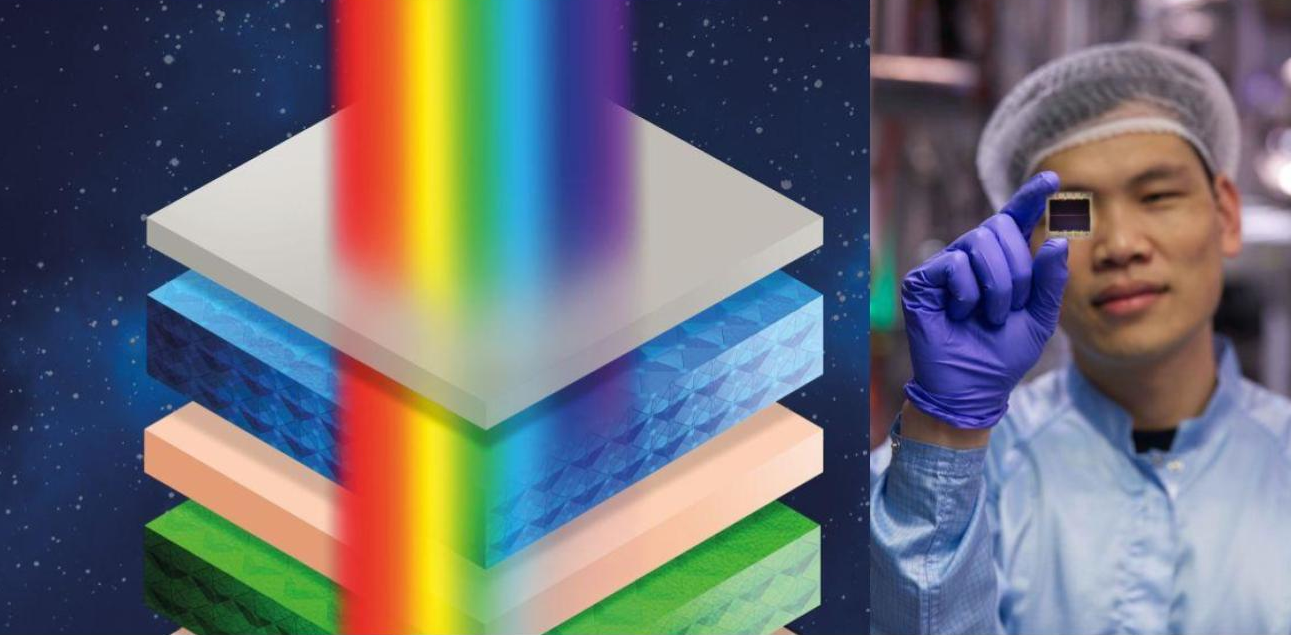

These innovative solar cells utilize multi-layered structures of titanium oxide and selenium. Researchers successfully enhanced the adhesion between these layers, significantly improving energy conversion efficiency compared to previous studies. Although experiments showed a conversion efficiency of 4.49%, which is lower than commercial silicon panels (20-25%), these titanium panels could outperform silicon in long-term use, especially in unpredictable climates.

Titanium: A Robust Alternative to Silicon

Silicon has long been the primary material for solar panels, but it has significant drawbacks such as fragility and a shorter operational life in harsh environments. Titanium, on the other hand, boasts exceptional strength, corrosion resistance, and longevity, making it an ideal material for challenging environments like salty coastal areas and arid deserts. This reduces the need for frequent panel replacement, lowering overall costs, decreasing waste, and making renewable energy tools more sustainable.

The new panels have already undergone testing in volatile Japanese environments, specifically on the islands of Okinawa and Kyushu, where they demonstrated resilience against storms and high salinity levels.

Cost-Effective Titanium Extraction

Historically, titanium extraction has been a costly and energy-intensive process, making it prohibitive for widespread use. However, the Japanese research team has overcome this challenge with an innovative extraction process using yttrium, a rare-earth element used in many advanced technologies.

This process involves reacting molten titanium with yttrium to remove oxygen from the titanium ore. This technique has successfully significantly reduced production costs, making titanium a more economical option for solar panel manufacturing.

Considerations and Future Outlook

There is one drawback to this new process: the resulting product contains up to 1% yttrium. While this might affect titanium's durability and corrosion resistance in other applications requiring complete purity (like aerospace or medical technologies), the presence of a small percentage of yttrium is not an issue for solar panel manufacturing.

This research was published in the journal "Solar Energy Materials and Solar Cells."