As our dependence on lightweight, high-energy batteries continues to grow, the demand for advanced battery technologies intensifies. Consequently, researchers are tirelessly innovating to enhance the energy density and overall performance of these batteries.

Researchers at the University of Science and Technology of China (USTC) have developed an innovative lithium-hydrogen battery that incorporates hydrogen gas as a key component. This groundbreaking battery is notable for utilizing two of the lightest elements, lithium and hydrogen. Unlike traditional lithium batteries, which typically use lithium compounds as the cathode (positive electrode), this new battery employs lithium as the anode (negative electrode), setting it apart in both composition and functionality.

Researchers have successfully designed a prototype of the Li-H battery system, demonstrating outstanding energy storage capabilities. Test results reveal an impressive energy density of 2825 Wh/kg, coupled with a consistent voltage of approximately 3 volts. Remarkably, the battery retained 99.7% of its energy during charge and discharge cycles, highlighting its exceptional energy storage efficiency and long-term stability.

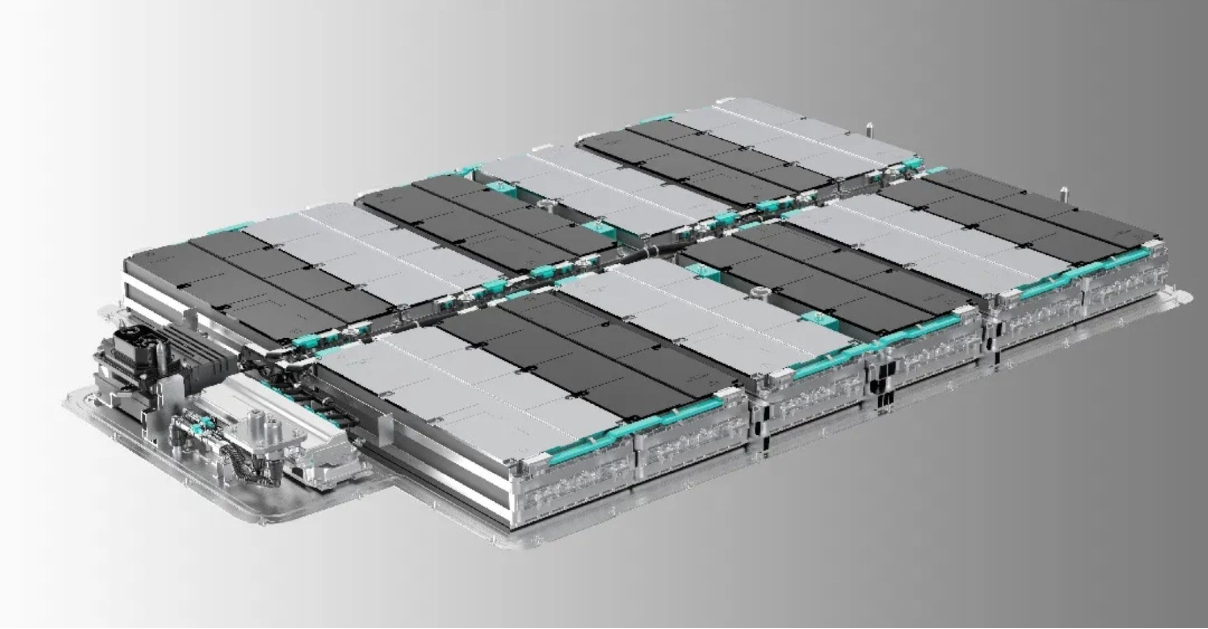

Battery Components

The negative electrode (anode) is composed of lithium metal, while the positive electrode (cathode) features a carbon layer coated with platinum, known as the hydrogen cathode for its role in distributing hydrogen gas within the cell. The electrolyte, positioned between the two electrodes, is made of lithium aluminum titanium phosphate. This solid material ensures efficient transfer of lithium ions while minimizing undesired chemical reactions.

Charging & Discharging

During battery discharge, lithium in the anode converts into positive lithium ions (Li⁺) and releases electrons (e⁻). These electrons flow through the external circuit to the cathode, generating an electric current that powers the device. Meanwhile, the lithium ions travel through the solid electrolyte to the hydrogen cathode, where hydrogen gas reacts with the ions, forming lithium hydride (LiH).

During the charging process, electrons flow back to the anode through the external charger, while lithium ions (Li⁺) travel through the electrolyte and combine with the anode, forming lithium metal. Simultaneously, hydrogen gas is released at the cathode, completing the electrochemical reaction.

To reduce production costs, the team also developed a lithium-hydrogen battery without an anode, where most of the lithium metal was replaced with lithium salts. This model achieved high energy storage efficiency during a few cycles and still needs more experiments to increase its reliability as a viable option.

Cost and Production

To reduce production costs, the research team developed an anode-free lithium-hydrogen battery, where most of the lithium metal was replaced with lithium salts. This model demonstrated high energy storage efficiency during initial cycles. However, further experiments are needed to enhance its reliability and viability as a long-term solution.

Although the cost is higher compared to the prevailing batteries today, its high energy density makes it ideal for numerous applications such as space and remote locations where ensuring energy supply takes priority over cost. Additionally, efforts to reduce costs through the use of anode-free batteries may help bring it closer to practical applications.

Securing hydrogen for the battery, which requires pressure-resistant tanks, is not considered a limiting factor for its future use. With the continuous evolution of hydrogen technologies, solutions to current complexities are likely to emerge, making the integration of hydrogen into battery systems more feasible.

The study was published in the journal Angewandte Chemie International Edition.