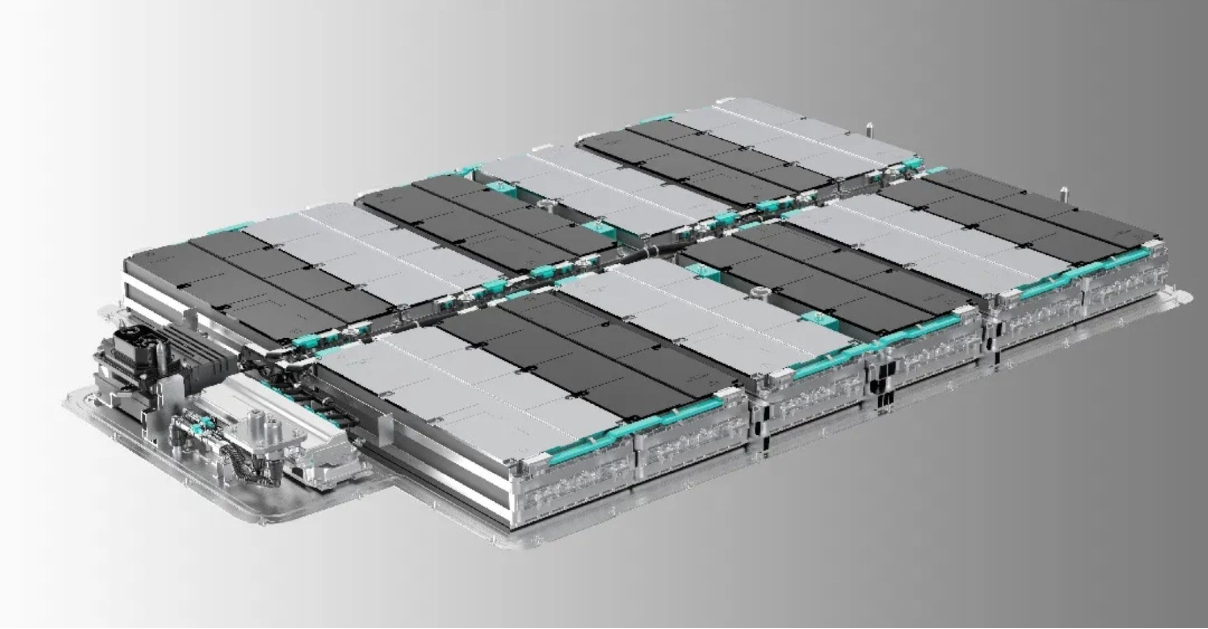

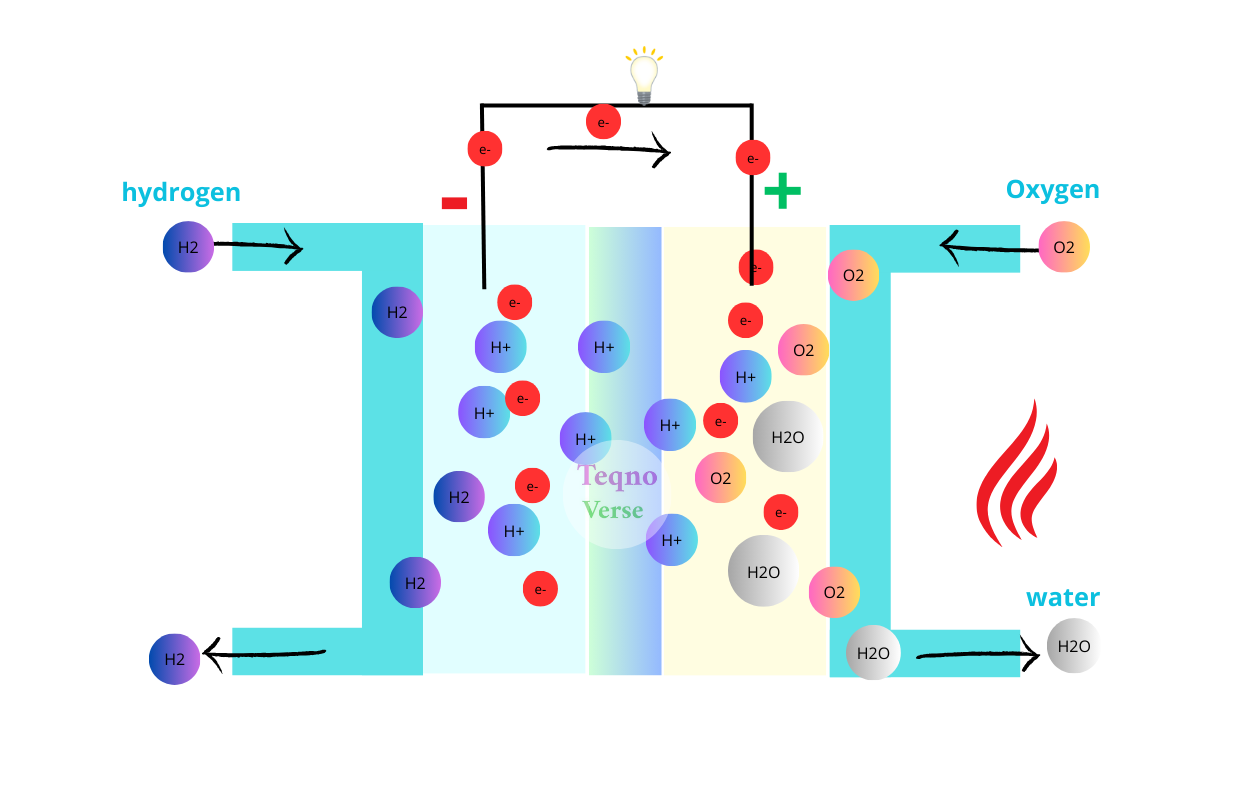

Solid-state batteries represent the next generation of electric batteries. Unlike widely used liquid-state batteries such as lithium-ion, they do not use a liquid electrolyte between the electrodes but rather solid electrolytes, making them smaller, lighter, more energy-dense, and safer.

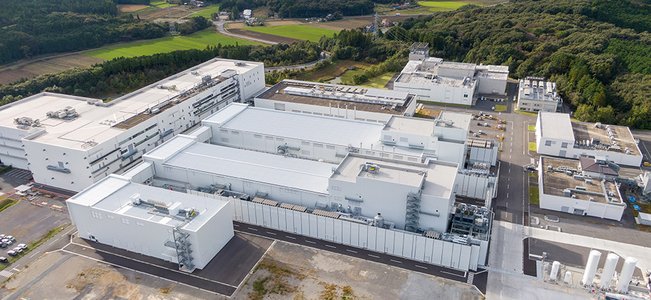

Japanese company Honda has officially unveiled its first pilot production line for solid-state batteries. The factory spans approximately 27,400 square meters and will begin pilot production in early 2025.

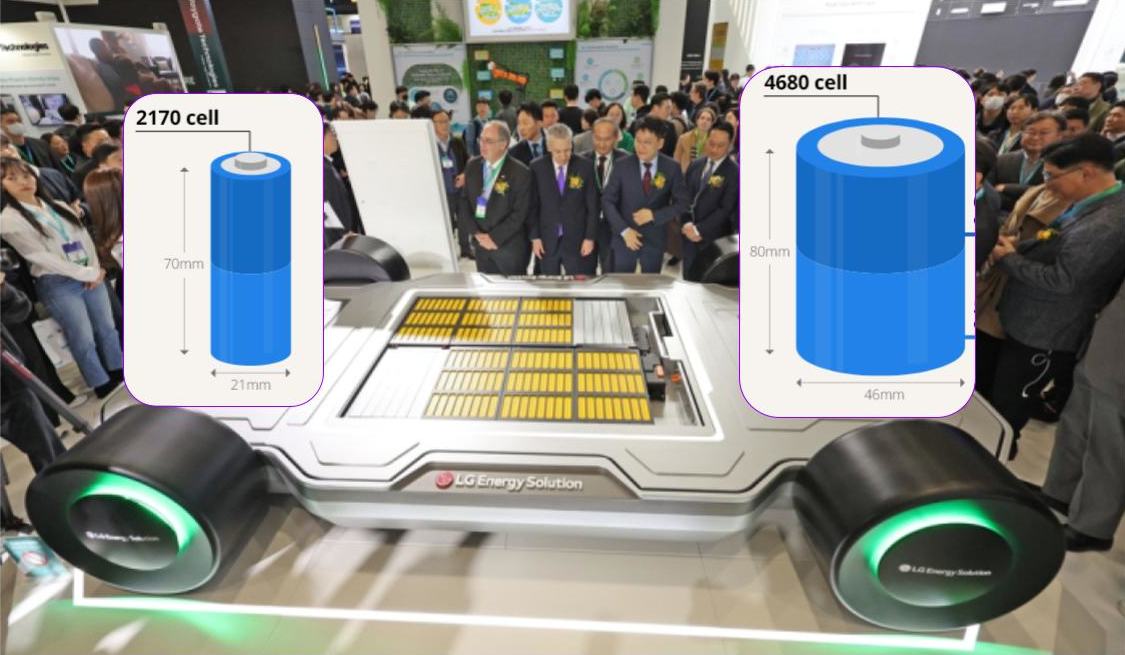

The manufacturing and assembly of all battery components will be tested: the negative electrode, the positive electrode, a solid electrolyte layer between them, and a case to compactly and safely assemble the cells together. Honda aims to improve technology and processes through this pilot production line before moving to full-scale mass production in the second half of this century.

The cost of solid-state batteries is one of the biggest factors delaying their widespread adoption. Honda is trying to improve productivity and reduce production time and cost through technical innovations in battery manufacturing and by improving production control and energy consumption techniques. Its expertise in mass production techniques makes it better positioned to produce batteries at an affordable cost.

Honda will announce the specifications of the battery cells it will produce, in order to integrate them into electric vehicles it plans to use, starting with electric bicycles and cars, and extending to drones and electric aircraft.

Samsung announced in August that it had started working on a production line for a solid-state battery with an energy density of 500 Wh/kg, which can be charged in 9 minutes and provides a range of up to 1000 kilometers for a car, and expects to start operating it in 2027.