Initially, wind turbine blades were made from wood due to its availability and ease of fabrication. However, as turbines increased in size and power, wood became less practical due to its limited durability and lifespan. This led to the development and adoption of alternative materials such as metals and composite materials like lightweight and durable carbon fiber, which delivered enhanced performance and extended lifespan.

The Return to Wood

In recent years, there has been renewed interest in wooden wind turbine blades. Wooden blades are biodegradable and recyclable, making them more sustainable and less harmful to the environment. Additionally, they can be more economical, requiring less energy to produce, and thus significantly reducing carbon dioxide emissions.

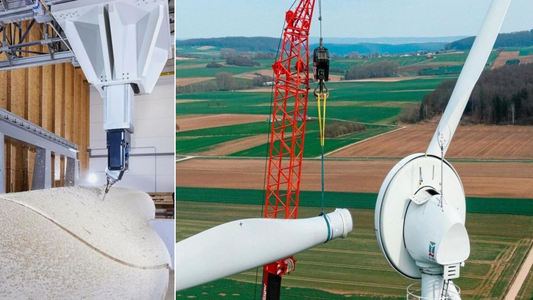

One of the leading companies in this field is the German company Voodin Blade Technology. They use Laminated Veneer Lumber (LVL), an engineered wood product made from thin layers of wood bonded together, making it strong and durable, and suitable for use in turbine blades.

The company has installed 19.3-meter wooden blades in Germany, demonstrating their effectiveness. The manufacturing process for these blades is simpler as it does not require molds and consumes less energy, making them about 20% cheaper than those made from traditional composite materials and producing 78% less carbon dioxide emissions during manufacturing.

Latest Developments: The World’s Longest Wooden Blades

In collaboration with Senvion, Voodin Blade Technology is developing and testing the world’s longest wooden wind turbine blades, which are expected to be over 50 meters in length. Senvion will conduct a comprehensive feasibility study to evaluate the technical, economic, and environmental potential of these wooden blades, followed by the installation and testing of prototype components on a 4.2 MW turbine platform. Testing is scheduled for late 2026 and early 2027 in Europe.

Reintroducing wooden wind turbine blades represents a significant step towards more sustainable and cost-effective solutions. If proven robust and durable at larger sizes, wooden blades could become an ideal solution for turbines, potentially replacing composite materials currently used in turbine manufacturing.